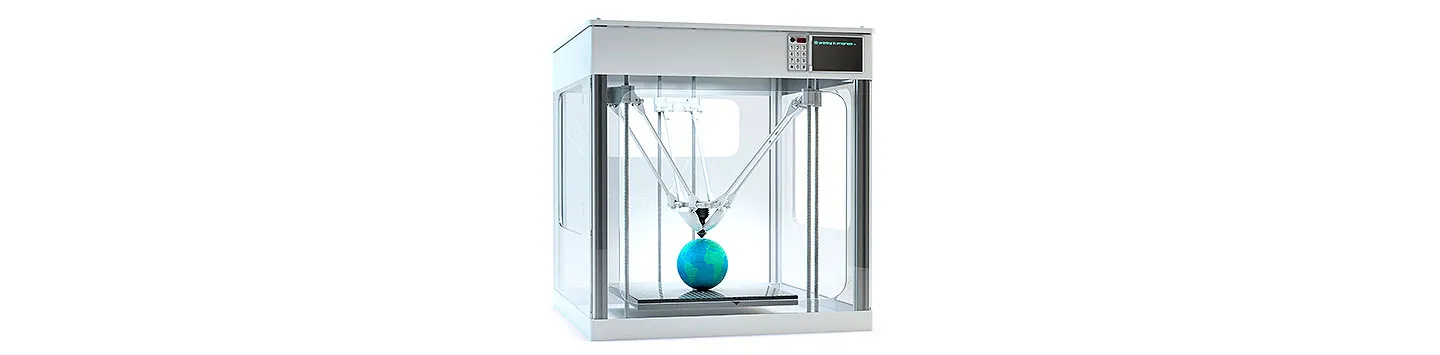

As an effective alternative to mass production, 3D printing is capable of economically producing small quantities in local markets, making goods to order based on customer preferences, and generating little waste. 3D printing also has the potential to disrupt the Chinese economy as its manufacturing is based on economies of scale and the use of low-skilled workers. The ability of 3D printing to integrate many components into one product has major implications for supply chain relationships. This paper contrasts 3D printing with traditional manufacturing and mass customization. It explores the disruptive effects of 3D printing and examines key managerial issues in implementing 3D printing. Strategies to compete against 3D competitors (niche-based products, mass customization, inventory-based strategies, and outsourcing) are discussed.